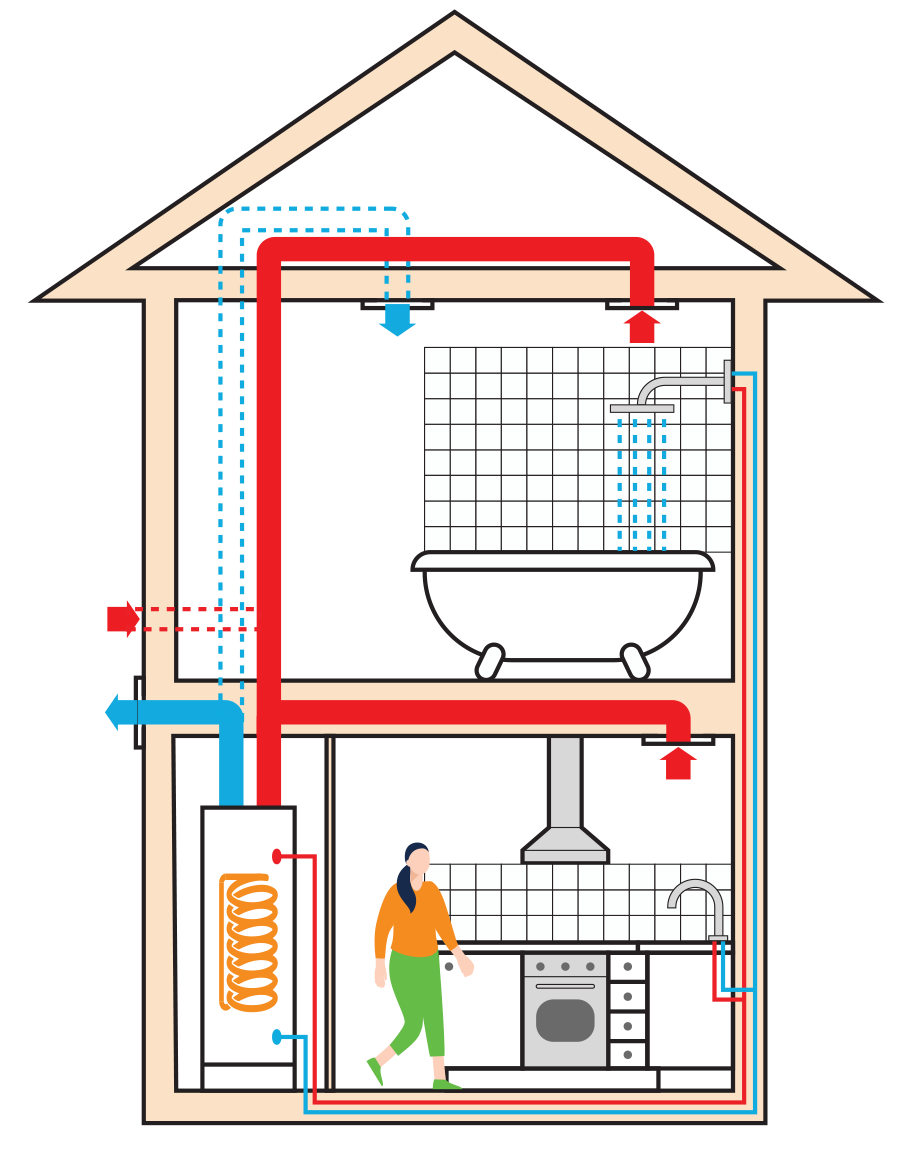

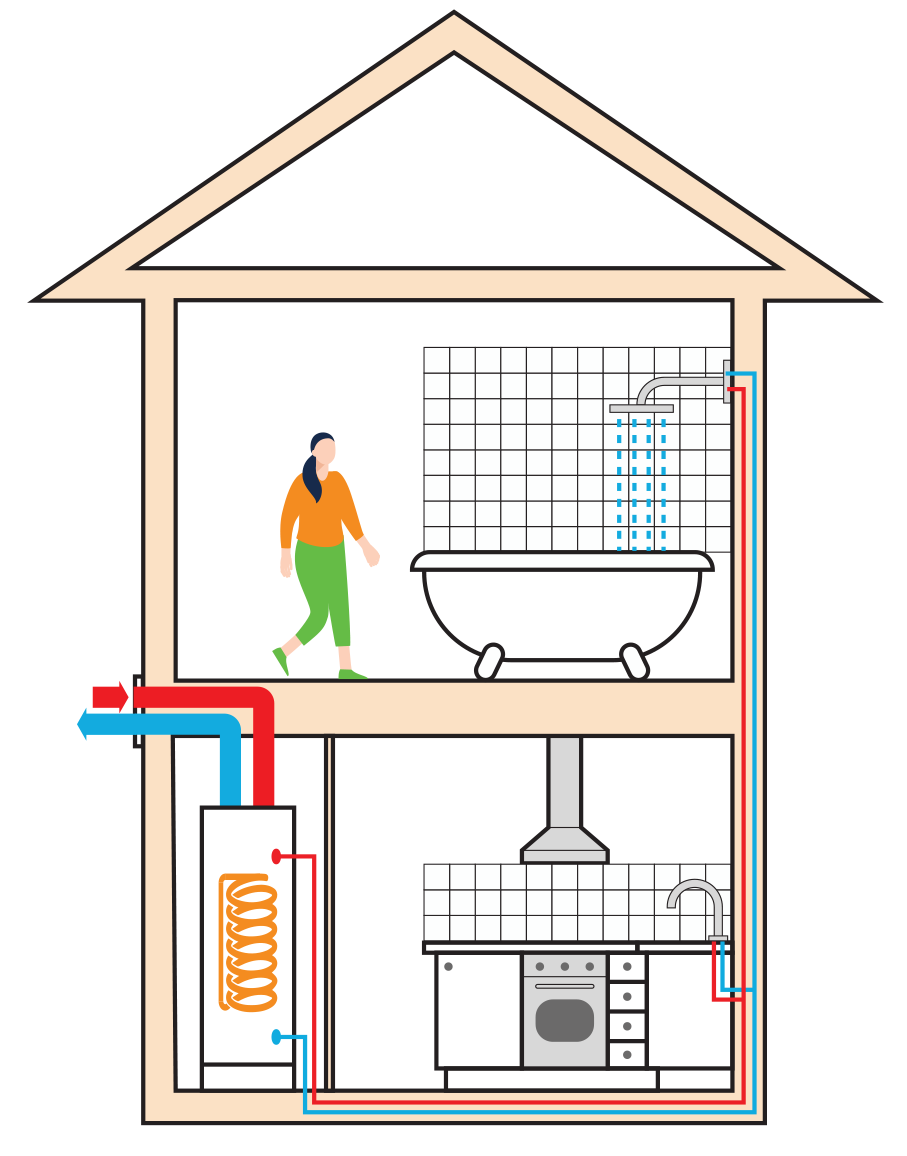

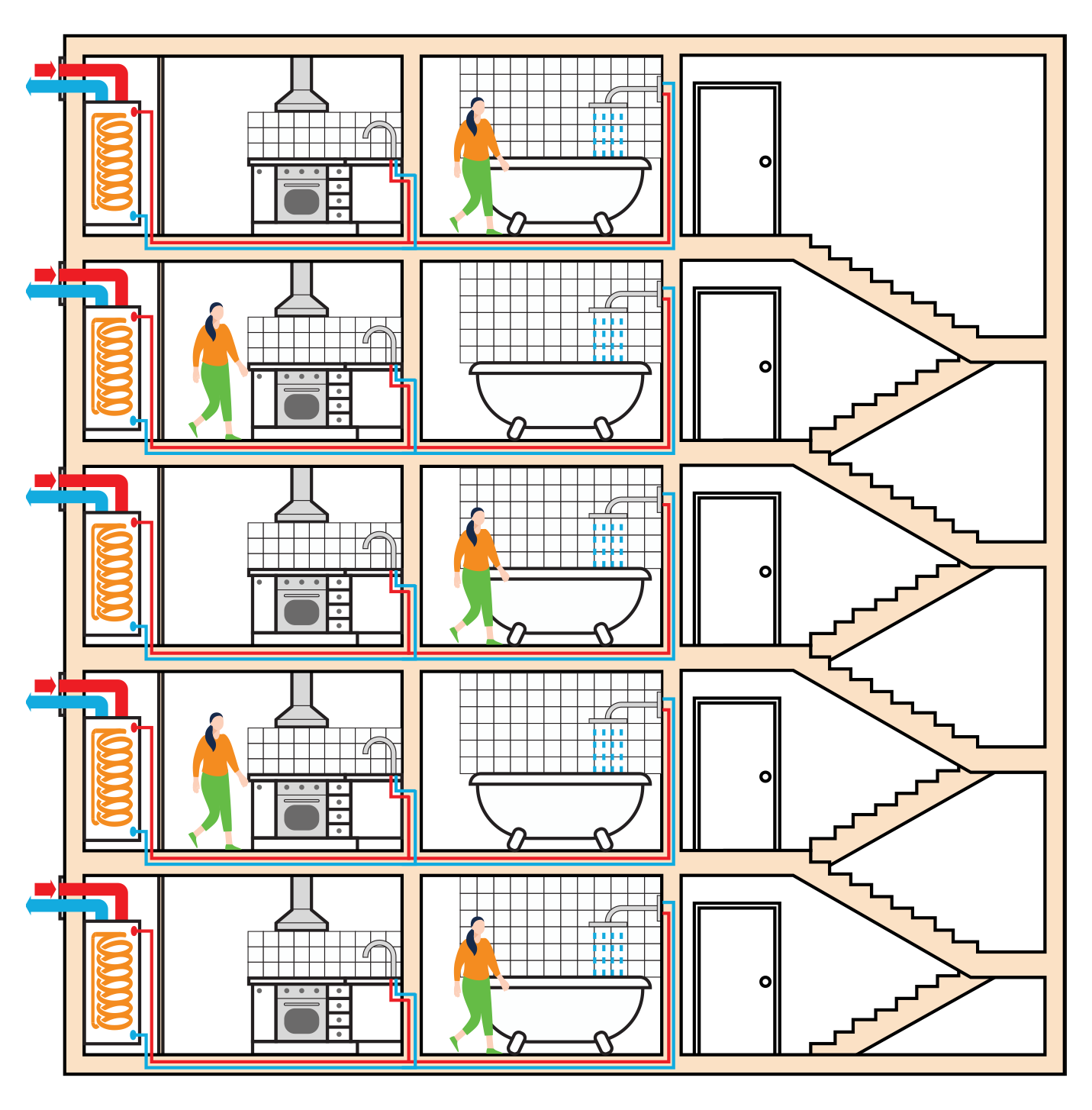

- Use of an air heat pump system can significantly reduce your energy bills as you are capturing and redirecting existing heat.

- Generating energy using heat in waste air takes advantage of natural resources reducing reliance on fossil fuels.

- Air heat pumps are able to extract heat from air temperatures as low as 15 degrees.

- Unlike many of their alternatives, air heat pumps are not at risk of combustion or of emitting harmful gases. Therefore, they are safe and require far less maintenance.

- The unit can directly replace the existing direct/indirect hot water cylinder when used in conjunction with existing conventional boilers.

- During the non-heating season, it can be used as the sole hot water cylinder heat pump with the secondary boiler not in use at all.

- Compatible with solar energy, the unit can work with solar thermal panels (Model-S) or with solar photovoltaics (all models).

- Easy integration with Photovoltaic Panels is possible via a dedicated solar controller (supplied separately).

- Air heat pumps compliment underfloor heating systems as they are both optimised to run at a lower water delivery temperature

Book an appointment with us to learn more about whether exhaust air heat pump installation can benefit your home.